Coolant Tank Pumping System

Complete control solution for a coolant tank pumping system for Rolls Royce / Able Engineering Ltd

Woodward Group was commissioned by Able Engineering LTD to provide and install a complete control solution for a coolant tank pumping system for Rolls Royce’s new machine facility in Derby.

We were responsible for the project management, and oversaw the design, manufacture, installation and commissioning of the Coolant Tank Pumping System, which enabled the topping up of coolant on multi-axis CNC machinery at Rolls Royce.

CLIENT:

Rolls Royce / Able Engineering Ltd

SECTOR:

Aerospace

PROJECT:

Coolant Tank Pumping System

BUDGET:

£65,000

WOODWARD DIVISION:

Company wide

REQUIREMENT:

To provide and install a complete control solution for a coolant tank pumping system.

PROCESS:

Tender

BACKGROUND:

Able Engineering commissioned Woodward Group to undertake the project management, design, manufacture, installation and commissioning of a comprehensive Coolant Tank Pumping System, to enable topping-up of coolant on multi-axis CNC machinery at Rolls Royce’s new machine facility in Derby.

SOLUTION & OUTCOMES:

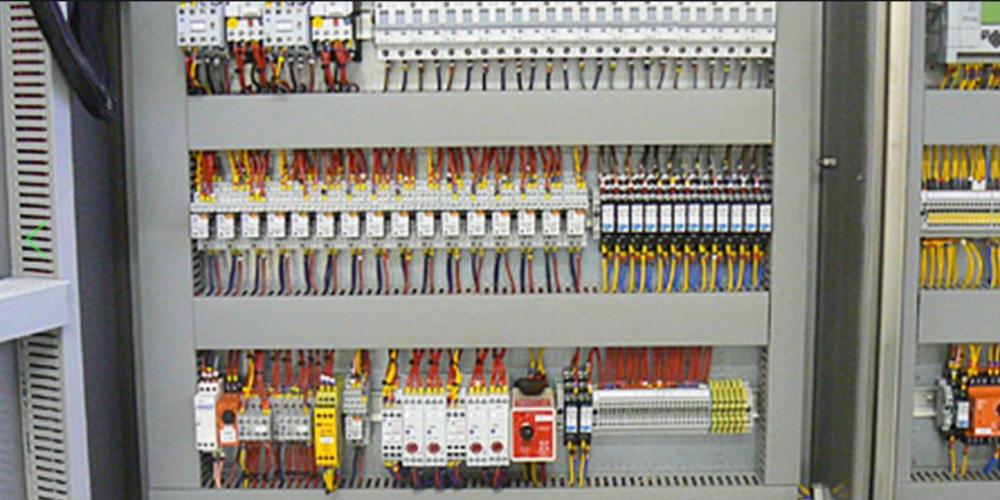

Woodward Group assigned a team to the project, that began work with Able Engineering on the full design of the control panel layouts, schematic diagrams, assembly details, cable installation drawings, and cable schedules, all subject to approval by Rolls Royce.

The system comprised of:

- Several local coolant delivery control station panels

- Regulated local pumping units fed from a common coolant tank

- Waste coolant being directed to an external storage tank

- All with fully-automated level controls

Small power was sourced from local, nominated distribution boards via high-level trays to the local control panels at the pumping stations, with locally installed cabling and connections to the pneumatic pumps and level controls.

Each local station interfaces to the common waste tank level control via high-level trays to an external tank interface.

Control systems and safety interlocks were commissioned in-line with Rolls Royce’s permit to work and strict handover procedures. We also provided the user with:

- Operation manuals

- Control specification

- Drawings