Equipment and Machinery Hire

Heating & mixing control system for Hilltop Honey

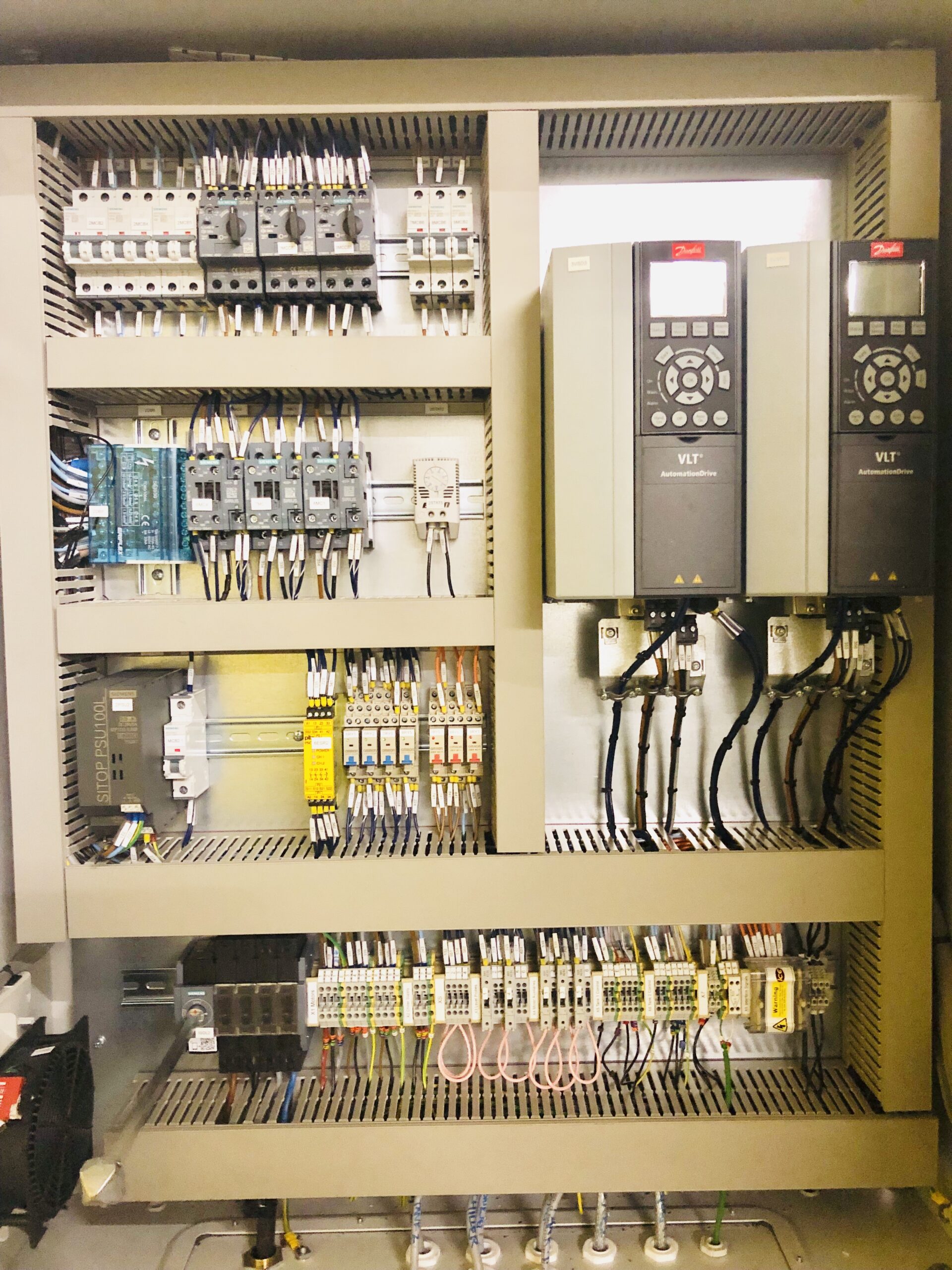

We worked with Hilltop Honey to design, plan and install a complete electrical control and power solution for a new heating and mixing process plant – a unique project, as the company was moving from prototype to mass production.

Woodward Group designed and built a control system that allowed the company to store honey at the correct temperature and pump it from storage to production, where it would then either be heated or chilled.

We worked closely with the Hilltop Honey team to ensure the scope was fully understood, and we offered advice where needed. The system was a complete success, and the company is now looking to expand projection by another 150%.

CLIENT:

SECTOR:

Food production

PROJECT:

Heating & Mixing control system.

BUDGET:

£60,000

WOODWARD DIVISION:

Company wide

REQUIREMENT:

Design, plan and install of a complete electrical control and power solution for a new heating and mixing process plant.

PROCESS:

Tender

BACKGROUND:

Founded in 2011, Hilltop Honey was moving from protype to mass production of its packaged honey at its 14,000 sq. ft HQ, and needed a bespoke control system that enabled them to store honey at the correct temperature, and then pump the honey from storage to production, where the honey is then heated or chilled.

SOLUTION & OUTCOMES:

Conducting a 360-degree review of the production process and facility to ensure we fully understood the specific requirements, we developed a solution that exactly matched all operational requirements, created and installed with supporting advice to the Hilltop team along the way.

Working in close consultation with the client throughout, Woodward Group designed a bespoke solution that encompasses an electrical control solution that is voted a ‘complete success’ by Hilltop Honey, which is now planning to expand production by more than 150%.