Hazardous area storage facility for RASE Distribution

Woodward Group supplied RASE Distribution, one of the UK’s leading independent logistics providers to the packaged hazardous goods sector, with a new explosive atmosphere storage facility.

RASE specialises in the storage and handling of packaged chemicals for many leading global chemical manufacturers, managing over 35,000 square metres of high quality, secure facilities. The new facility will safely store phosphine and arsine, which are chemicals used to make hand sanitiser gel, to support the ongoing fight against COVID-19.

Woodward Group was awarded the contract following successful completion of ongoing ATEX works at H.W. Coates, a partner of RASE, involving maintenance and electrical installation work in potentially explosive atmospheres.

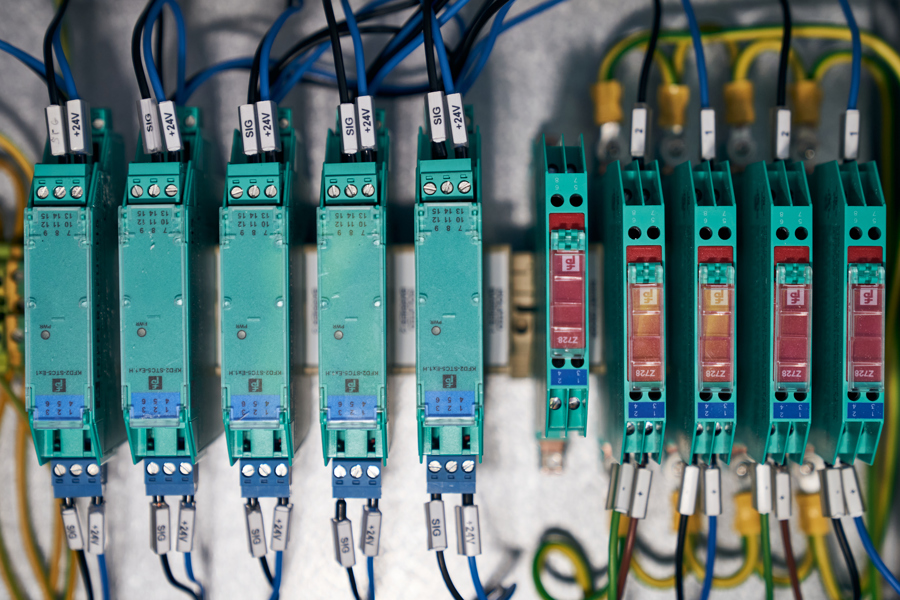

As controlled substances, phosphine and arsine are required to be stored and distributed under licensed conditions, but storage can only be licensed once regulated standards are met. Woodward Group was therefore contracted to undertake works including electrical distribution, lighting and power, gas detection, fire detection, and security alarms that meet complex industry regulations.

Having listened carefully to and understood RASE’s specific requirements, we carried out a tailored electrical design study for the complete project and worked in partnership with sub-contractors to compile a gas and flame mapping survey. We also fitted and tested the complete electrical installation.

With a fully compliant system, RASE has been able to obtain insurance for storage and distribution. The system also ensures safe methods of working for employees handling these products, meaning they won’t be exposed to avoidable risks.

CLIENT:

SECTOR:

Transportation and storage of hazardous goods and materials

PROJECT:

Hazardous area storage facility

PROJECT VALUE:

£250,000

WOODWARD DIVISION:

ATEX